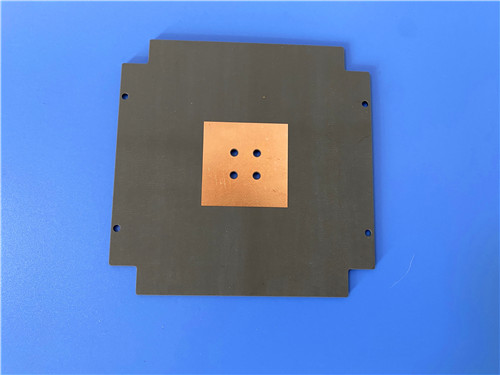

F4BTMS1000 High-Frequency PCB with 1.905mm Thick Core for Aerospace and Radar Applications

1.Product Introduction: Advanced Ceramic-PTFE Composite

The F4BTMS1000 represents a significant technological advancement in PTFE-based circuit materials, combining ultra-fine glass fiber reinforcement with nano-ceramic additives to achieve superior high-frequency performance. This next-generation material minimizes the fiber weave effect while delivering exceptional dimensional stability (CTE 16/18/32 ppm/°C) and a stable dielectric constant of 10.2 at 10GHz. The standard RTF copper foil construction reduces conductor loss and provides excellent peel strength, making it ideal for demanding aerospace, radar, and satellite communication systems where reliability and signal integrity are critical.

2.Key Material Properties (F4BTMS1000)

High Dielectric Constant: 10.2 @10GHz

Low Loss Tangent: 0.0020 @10GHz (0.0023 @20GHz)

Excellent Thermal Management: 0.81 W/mK conductivity

Temperature Stability: -320 ppm/°C ΔDk (-55°C to 150°C)

Moisture Resistance: 0.03% absorption

Mechanical Reliability: 16/18/32 ppm/°C CTE

3.PCB Construction Specifications

| Parameter | Specification |

|---|---|

| Base Material | F4BTMS1000 |

| Layer Count | 2-Layer |

| Board Dimensions | 349mm × 361mm (±0.15mm) |

| Minimum Trace/Space | 8/7 mils |

| Minimum Hole Size | 0.3mm |

| Via Type | Through-Hole Only |

| Core Thickness | 1.905mm (75mil) |

| Finished Thickness | 2.0mm |

| Copper Weight | 1oz (35μm) outer layers |

| Via Plating Thickness | 20μm |

| Surface Finish | Immersion Gold (ENIG) |

| Silkscreen (Top/Bottom) | None / None |

| Solder Mask (Top/Bottom) | None / None |

| Electrical Testing | 100% tested prior to shipment |

4.PCB Stackup:

Copper layer 1 - 35 μm

F4BTMS1000 Core - 1.905 mm (75mil)

Copper layer 2 - 35 μm

5.Board Statistics

Components: 51

Total Pads: 169

Thru Hole Pads: 67

Top SMT Pads: 102

Bottom SMT Pads: 0

Vias: 67

Nets: 2

6.Manufacturing & Quality Standards

Artwork Format: Gerber RS-274-X

Quality Standard: IPC-Class 2

Availability: Worldwide shipping

7.Technical Advantages

Nano-Ceramic Enhanced: Reduces dielectric loss and anisotropy

Military-Grade Reliability: Withstands -55°C to 288°C operation

RTF Copper Foil: Standard feature for reduced conductor loss

Broad Frequency Range: Stable performance up to 20GHz

Dimensional Stability: Minimal Z-axis expansion (32 ppm/°C)

8.Target Applications

Aerospace equipment, space and cabin equipment

Microwave, RF

Radar, military radar

Feed networks

Phase-sensitive antennas, phased array antennas

Satellite communications, and more.